2021. 3. 16. 22:01ㆍ카테고리 없음

Step by step instructions on how to check an automotive fuel pump and pressure regulator, this article pertains to most fuel injected vehicles.

Difficulty Scale: 4 of 10

Fuel Injection & Noid Lights. Home Diagnostics Fuel Pump Testers. ATD-5657 Deluxe Vacuum and Fuel Pump Tester Follow us: Facebook. A fuel pump is essential for a car to run properly in that it helps deliver fuel to the engine. If the fuel pump is not working properly, it can put you and whoever else is in the car in serious danger. While testing your fuel pump may sound difficult, it is actually quite simple with the proper tools. If a car stops and has not run out of petrol, check whether there is petrol in the carburettor. If there is not, there is a fault in the fuel system. A mechanical-pump drive hardly ever fails — though signs of wear may appear on the cam and operating lever, linkages and pins. Diaphragms can leak.

Begin with the vehicle on flat ground, in park with the emergency brake on, engine 'OFF'. How to make an efficnt user manual. (No smoking or open flame.)

Step 1 - Locate the vacuum line which is attached to the fuel pressure regulator and remove it, this line should be free of fuel, if fuel is observed the regulator has failed. (Note: Not all vehicles are designed with a pressure regulator.)

Step 2 - Once the inspection for the fuel pressure regulator is complete reinstall the vacuum line.

Step 3 - Locate and remove the protective cap which will allow the fuel pressure gauge hose to be attached.

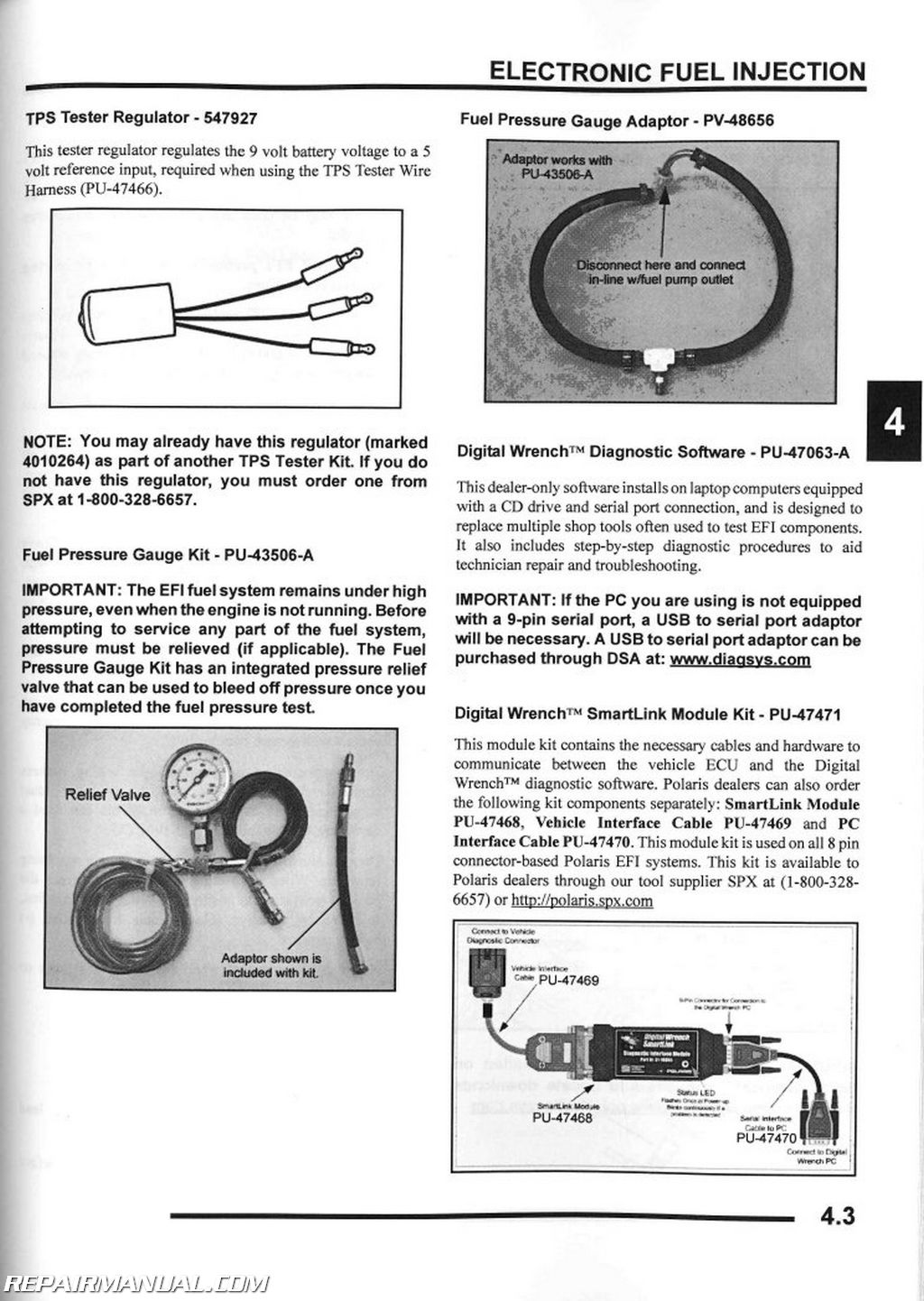

Step 4 - Next, remove the fuel pressure test gauge from its packaging. The gauge shown is a professional gauge kit, but any attachable fuel pressure gauge will work.

Step 5 - After fitting the gauge with the appropriate adapter attach the gauge line to the fuel test port. If no test port is provided, a fuel filter adapter is needed, this adapter is connected to, or takes the place of the fuel filter.

Step 6 - Once the fuel gauge had been attached, turn the ignition key to the 'ON' position. The gauge should jump up to between 45 psi and 58 psi for most (DPI) direct port inject systems, throttle body injection (TBI) are between 13 and 17 psi. This means the pump is working along with the electrical portion of the system. If no fuel pressure is present, check the fuel pump relay and fuse in the PDC (power distribution center.) If there is still no fuel pump operation access the fuel pump power feed wire, there are a few ways to do this, a wiring schematic will call out the color wire used to energize the fuel pump. to find the color wire needed for testing, the best way to do this is with a service manual. Once you have found the color wire it should be located in the wiring harness near the fuel tank were the pump is located. Ground the test light and probe (pierce the wire's outer coating with the test light point) the wire, have a helper crank the engine over. If the test light illuminates and still no pressure the fuel pump had failed, if the test light doesn't illuminate the fuel pump control relay or wiring circuit has shorted.

Step 7 - While the engine is running, the fuel pressure should drop about 5 psi, to 52 psi., also try snapping the throttle, the fuel system pressure should jump up about 5 psi., this means the fuel pressure regulator is working properly. If the system fuel pressure does not respond inspect the vacuum feed line, if okay, the fuel pressure regulator has failed.

Fuling inverter dzb 200 user manual. It is highly valued by the users for its small size, strong functions and convenient installation, widely using in textile industry, dye printing, carving and food handling industries etc.Features1. Over-entering and down-out design makes it convenient for connecting wires in a small control cabinet and its appearance is neat3. General IntroductionDZB200Mmicro inverter is a small size inverter specially designing in light industries. Small size, convenient installation2.

Step 8 - While the engine is under load, the fuel delivery system is working at full capacity, this can cause the psi to drop slightly. (Note: Ideally the pressure should stay at 52 psi.)

Step 9 - If the fuel pressure is low under load or while idling the fuel filter could be clogged, or the fuel pump has failed.

Step 10 - After the test is complete install a shop towel at the base of the test port which will be used to gather excess fuel from the gauge hose.

Step 11 - While using the shop towel to gather excess fuel, loosen the pressure hose, fuel will begin to leak out.

Step 12 - Once the hose has been removed, fuel will continue to leak out, move the hose end onto a shop towel to collect excess fuel.

Step 13 - After the gauge hose has been removed, install the fitting dust cap.

Step 14 - Using a clean shop towel wipe the area free of fuel.

One testing is complete, inspect the area for fuel leaks.

Ricoh aficio mp 4001 driver. Choose a language from the drop down list. For users in Europe. Ricoh Manuals; All in One Printer; Aficio MP 4001; Ricoh Aficio MP 4001 Manuals Manuals and User Guides for Ricoh Aficio MP 4001. We have 3 Ricoh Aficio MP 4001 manuals available for free PDF download: Quick Start Manual, User Manual, Specification. View and Download Ricoh Aficio MP 4001 quick start manual online. Quick Start Guide. Aficio MP 4001 All in One Printer pdf manual download. Also for: 4001. The RICOH Aficio MP ® 4001/MP 5001 aligns perfectly with these strategies. Page 3 Improve Productivity Immediately Expect fast, high-quality results from the Ricoh Aficio MP 4001/MP 5001. It is equipped to help your office print, copy, scan, fax or distribute critical documents.

Vacuum Gauge And Fuel Pump Tester

Helpful Information

I find it outrageous that Comcast has not made anything available other than 'Quick Start' documents which provide very little information.Has anybody out there found any kind of a comprehensive PDF manual for the latest X1 cable box? Comcast has never posted X1 manuals. Arris user guide.

Some vehicles are not designed with a fuel pressure test port, in which case a fuel filter adapter must be used for the gauge connection.

A fuel pressure regulator is controlled by a diaphragm and spring combination in conjunction with intake manifold vacuum. When a fuel pressure regulator diaphragm ruptures, it allows raw fuel to enter the vacuum feed line and into the engine. This condition creates a rich black smoke from the tail pipe on start up and while running. Remove the vacuum line from the regulator, if fuel is present, the regulator has failed.

Some GM (CPI Injection) are designed with an internal regulator in which the intake manifold must be removed to access.

Most fuel pressure regulators are on the top of the fuel rail. If you cannot locate the fuel pressure regulator consult a repair manual.

Dasbet Fuel Pump Tester Users Manual Free

Tool and Supplies Needed

- Fuel pressure gauge kit

- Protective eye wear and clothing

- Flashlight

Best Practices

- Replace fuel pump and pressure regulator with quality replacement parts or premature failure could occur.